Capabilities and Competence

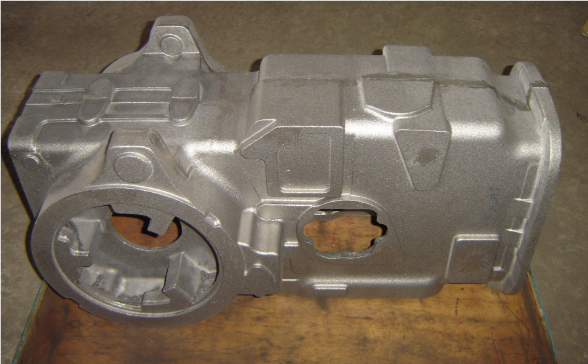

Sand castings of gray and ductile irons of the following types to radiographic/ultrasonic inspection standards:

Flake Graphite and Nodular cast irons - alloyed and unalloyed

Alloyed irons for special service conditions requiring resistance to abrasion, corrosion and high temperature

Alloys with special compositions for application specific requirements such as SiMo,Ni-hard, Ni-resist, Abrasion resistant Chromium alloyed white irons

Casting weights range from 300 grams to 5500 Kgs single piece in gray cast iron and to 2500 Kgs single piece in ductile iron.

Process Control

Thermal Analysis and process control software – ATAS (Adaptive Thermal Analysis System), PQDIT (Prime Quality Ductile Iron Technology ) for online assessment and precise control of melt parameters

IronCad and NovaFlow & Solid – 3D part modeling and simulation of mould filling and solidification.

Our Outsourced Services

Pattern manufacture

Wooden Patterns

Metal Patterns

Polystyrene and Epoxy patterns

Heat Treatment

Special Painting & coatings

Machining

We have tie ups with competent facilities that offer a wide variety of CNC machining with CMM Inspection:

HMC

VMC

Turning machines

Radiographic Testing (RT)

Ultrasonic inspection (UT)

Magnetic Particle Inspection

Memberships And Affiliations

Certification - Quality Systems